liberty

art of The Darkroom's ongoing look at Baltimore during and shortly after the end of the Great Depression (thanks to Yale's Photogrammar site). All captions are the original text provided with that image.

Due

to enemy U-boats during 1942, millions of tons of ships and cargo were

lost during WWII. This high loss necessitated the need for more ships

that were stronger, larger, and can hold vast amounts of cargo.

During 1942 the U.S. Maritime Commission chose 16 sites around the

nation to build what would be termed "Liberty Ships." Brunswick was one

of the towns chosen.

Due

to enemy U-boats during 1942, millions of tons of ships and cargo were

lost during WWII. This high loss necessitated the need for more ships

that were stronger, larger, and can hold vast amounts of cargo.

During 1942 the U.S. Maritime Commission chose 16 sites around the

nation to build what would be termed "Liberty Ships." Brunswick was one

of the towns chosen.

Headed by the J.A. Jones Construction Company, about 99 ships were built by the 16,000 plus employees of Brunswick's shipyards. In 1943 the first keel was laid for one of these 447 foot, 3500 ton steel vessels, vessels that sailed across the oceans anonymously so that the enemy would have no idea as to what these ships were up too. Four ships were produced each month, the last month of production, during the Battle of the Bulge, 6 ships were requested to be made. The patriotic citizens of Brunswick rallied around their shipyards and produced seven vessels to aid the war effort.

Each ship was christened with a name before setting off, most named after important men of the time and of the nation's history.

Upon war's end in 1945, the J.A. Jones Construction Company closed the shipyards, on their way out, they donated a model of one of the Liberty Ships that was used in training the employees. For many years this model sat at the foot of the St. Simons Island Causeway, eventually though, the model fell to ruins and had to be scrapped.

Around 1987 the local Navy League started raising funds to build a new model. On 23 August 1991 a brand new 23 foot vessel was completed, making it the "100th Liberty Ship" build by Brunswick. And, like all vessels before it, this ship was christened with a bottle of champagne and the name "City of Brunswick".

Ships Built in Brunswick

- Wooden templates are used as patterns for the laying out of a number of steel plates. This worker is carrying the templates for a gun foundation from the mold loft to the plate working section. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

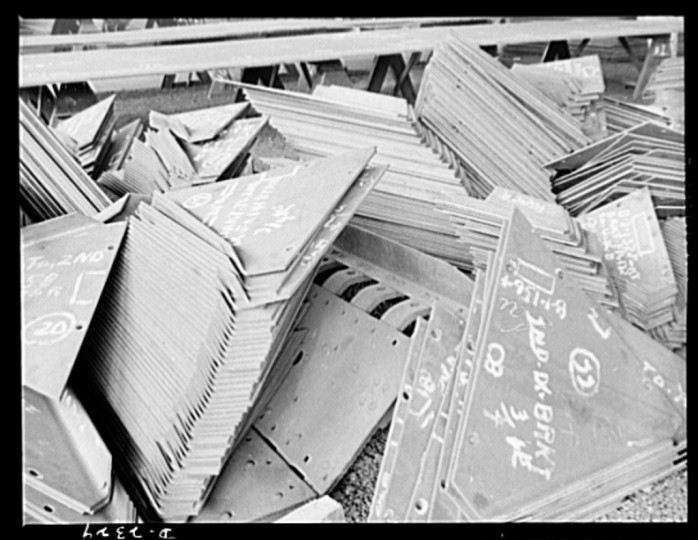

- These are shell frames and deck brackets ready to be welded between deck beams and frames for ship of the Liberty Fleet under construction at a large Eastern yard. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Wooden templates are used as patterns for the laying out of a number of steel plates. This worker is carrying the template for a gun foundation from the mold loft to the plate working section. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Wooden templates are used as patterns for the laying out of a number of steel plates. This worker is carrying the template for a gun foundation from the mold loft to the plate working section. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

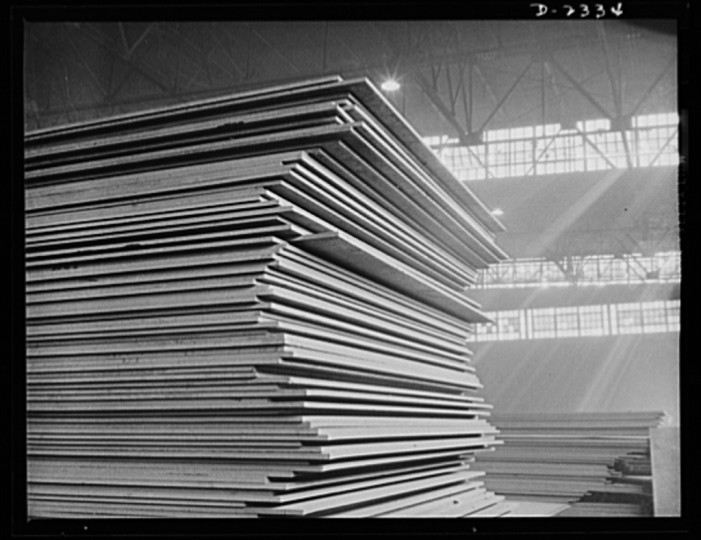

- These stacks of steel plate are in readiness for an uninterrupted flow toward the production line of a large Eastern plant fabricating sections for ships built at a nearby yard. This plant was formerly used for Pullman car construction. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

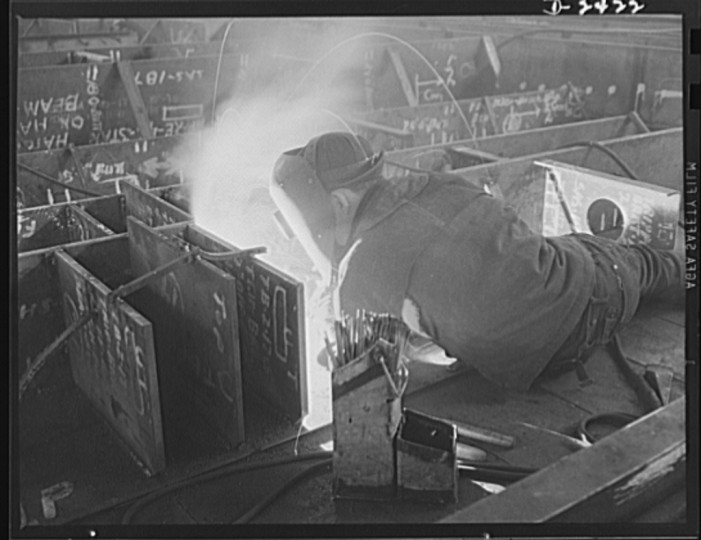

- These are shell frames and deck brackets ready to be welded between deck beams and frames for ship of the Liberty Fleet under construction at a large Eastern yard. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- These are shell frames and deck brackets ready to be welded between deck beams and frames for ship of the Liberty Fleet under construction at a large Eastern yard. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

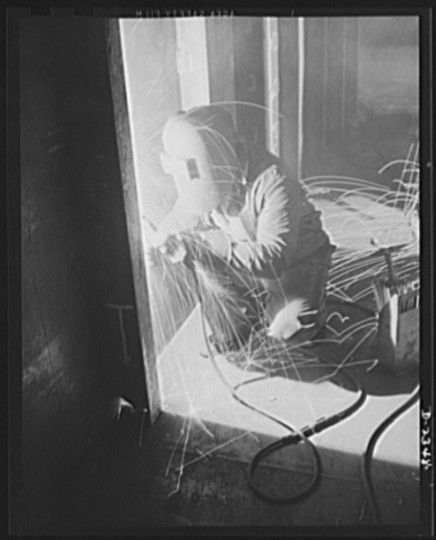

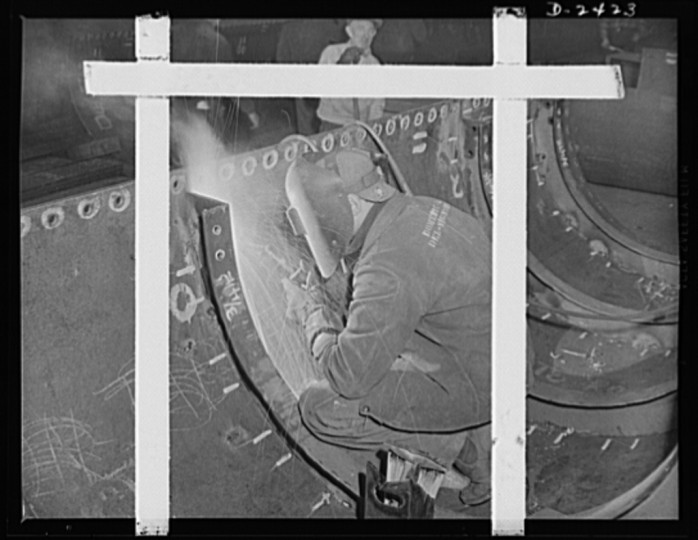

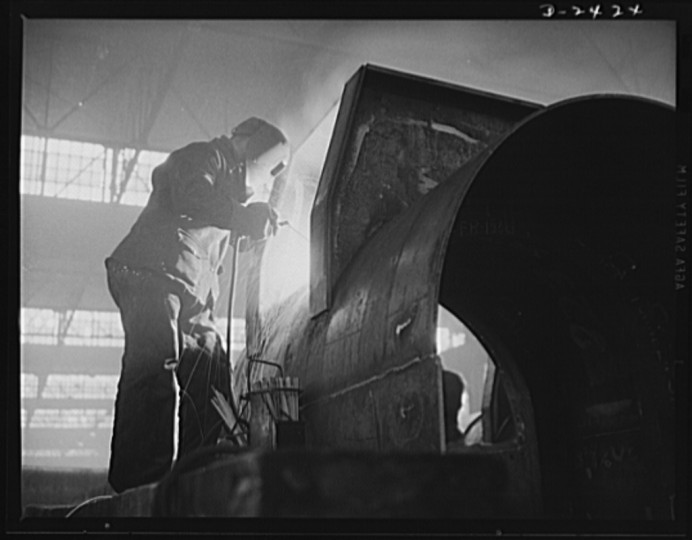

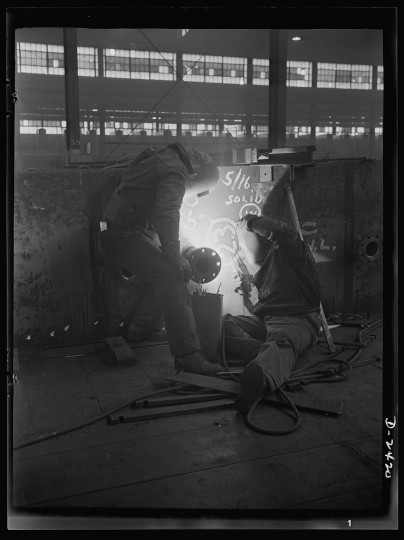

- Welding is one of the most important advances in shipbuilding during the present century with the torch resulting in immense savings in time, material and weight in the building of ships. This welder is joining side plates to angle frames forming section of the propeller shaft tunnels on a new member of Uncle Sam's Liberty ships, under construction at a large Eastern shipyard which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Welding is one of the most important advances in shipbuilding during the present century with the torch resulting in immense savings in time, material and weight in the building of ships. This welder is joining side plates to angle frames forming section of the propeller shaft tunnels on a new member of Uncle Sam's "Liberty fleet," under construction at a large Eastern shipyard.All parts are prefabricated in thus huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars

- These stacks of steel plate are in readiness for an uninterrupted flow toward the production line of a large Eastern plant fabricating sections for ships built at a nearby yard. This plant was formerly used for freight car construction. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards, Inc., Baltimore, Maryland 1941

- Steel plates of wasteless dimensions stacked ready for laying out, one of the first operations on the production line of multiply cargo ship construction. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Knee brackets ready to be welded between the ship's deck beams and frames ( or ribs) at the start of the production line. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- These workers are making the final fitting and checking of the rigging of the masthead of a new member of the "Liberty Fleet" at a large Eastern shipyard. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Here are prefabricated tanks and deck girder sections ready to be hoisted up and set in their place in one of the new merchant ships under construction in a large Eastern shipyard. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- This is the signal man of a riggers crew at a large Eastern shipyard. He is about ready to give the go-ahead signal to the operator of a large overhead electric crane. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Ratchets, turnbuckles and "dogs" hold these deck units of a new Liberty ship in place as a welder in a large Eastern shipyard uses the torch to fuse them

- Here are two members of the Liberty Fleet lying at anchor in the basin of a large Eastern shipyard, awaiting final fitting and rigging. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- These are prefabricated inner bottom tank sections, ready to be set in place and welded into a unit. Fabricated in an old freight car plant, they will be used in ships of the "Liberty Fleet" being built in a large Eastern shipyard. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Welding is one of the most important advances of the century in shipbuilding, saving time, steel and weight. This welder is working on the inside of a fuel tank in a ship of Uncle Sam's new "Liberty Fleet." All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Ships for war has meant the rehabilitation of numerous odd pieces of equipment unused for long periods, both in shipyards and in various other plants engaged in production of parts for ships. A discarded steam locomotive in a large Eastern plant is being turned up for use once again. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Welding is one of the most important advances in shipbuilding during the present century, with the resulting in immense savings in time, material and weight in the building of ships. This welder is joining side plates to angle frames forming sections of the propeller shaft tunnels on a new member of Uncle Sam's "Liberty Fleet," under construction at a large Eastern shipyard. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Ships for war has meant the rehabilitation of numerous odd pieces of equipment unused for long periods, both in shipyards and in various other plants engaged in production of parts for ships. Here an old junked flat car crane in a large Eastern plant is being turned up for use once again. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

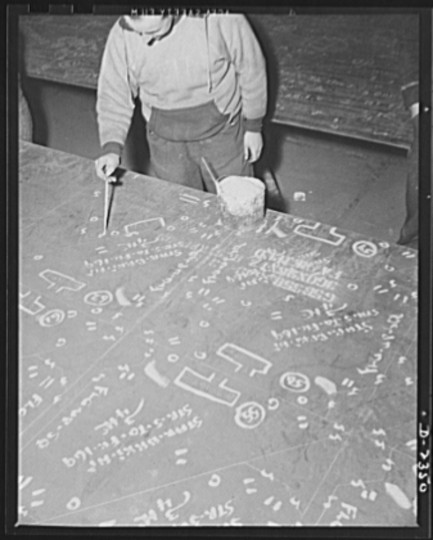

- This worker in the mold loft is painting over the marks made on steel plates from wooden templates, or patterns. The original marking is scratched onto the steel, and this man brings them out in white. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- This is one of the newer members of the "Liberty Fleet," lying at anchor in the basin of the large Eastern shipyard where she was built. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Electric welding is a vital skill in the building of Uncle Sam's new merchant fleet. This welder inserting a new rod in his charged holder, on one of the ships. Production scene in an Eastern shipyard. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Here a shipfitter and a crew foreman check the plans to make certain they properly locate a prefabricated section for a new ship, part of Uncle Sam's "Liberty Fleet," under construction at a large Eastern yard. Bethlehem- Fairfield Shipyards Inc., Baltimore, Maryland

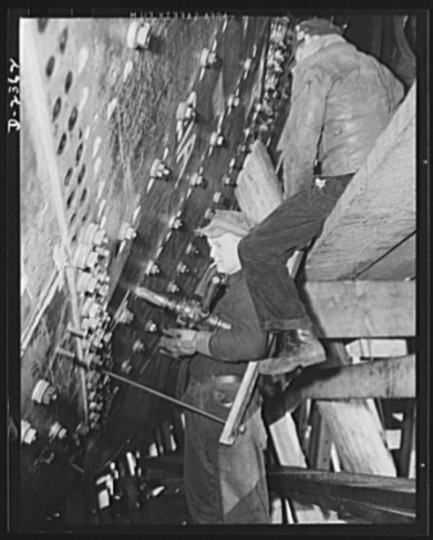

- Shell plates of a ship at the bow, where the inner plates are first bolted to the outer plates for added strength. The rivets are countersunk to be flush on the outer side. Production scene in a large Eastern shipyard. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- The propellers and shafting pieces are awaiting installation in the ships of the Liberty Fleet being built at a large Eastern shipyard

- This maze of rolling cranes, at a large Eastern shipyard is a typical scene in many large shipyards at work on ships for Uncle Sam's Navy and merchant fleet. Stocks of material are piled up for the cranes to take to vessels under construction so there is no delay in production while waiting for sections or materials. All parts are prefabricated in this Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- This maze of rolling cranes, at a large Eastern shipyard is a typical scene in many large shipyards at work on ships for Uncle Sam's Navy and merchant fleet. Stocks of material are piled up for the cranes to take to vessels under construction so there is no delay in production while waiting for sections or materials. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- This maze of rolling cranes, at a large Eastern shipyard is a typical scene in many large shipyards at work on ships for Uncle Sam's Navy and merchant fleet. Stocks of material are piled up for the cranes to take to vessels under construction so there is no delay in production while waiting for sections or materials. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

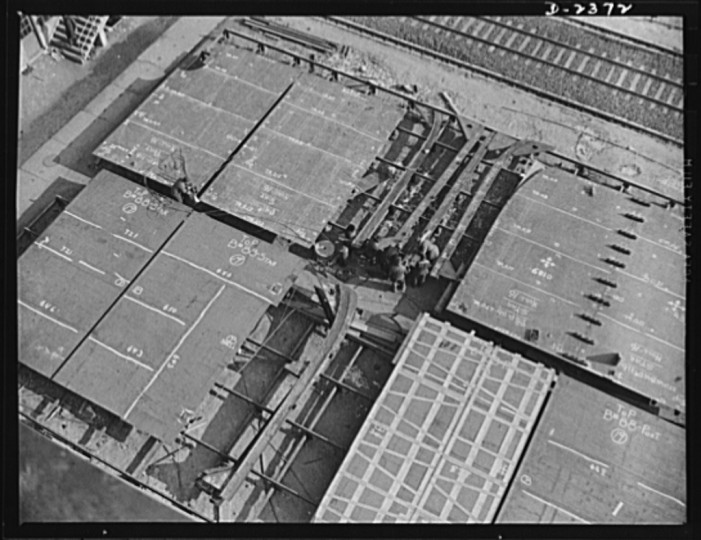

- A new vessel has just moved off these ways, and the keel is being assembled for yet another in a large Eastern shipyard. The bottom and side shell plating and the inner tank sections are being assembled. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars

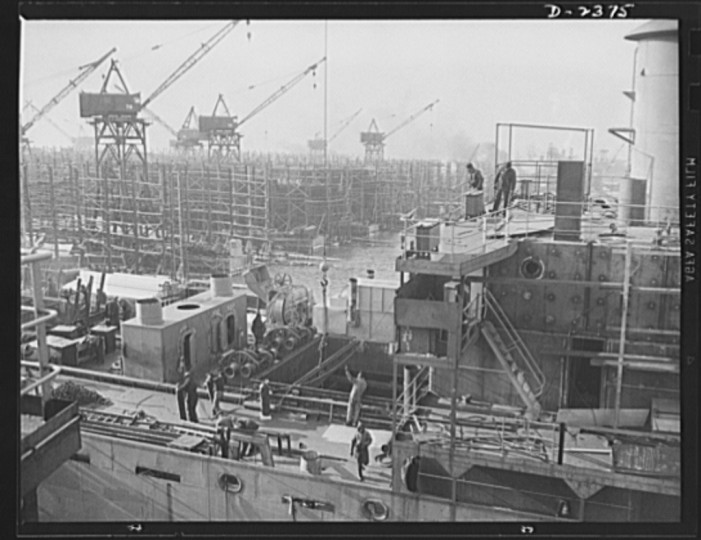

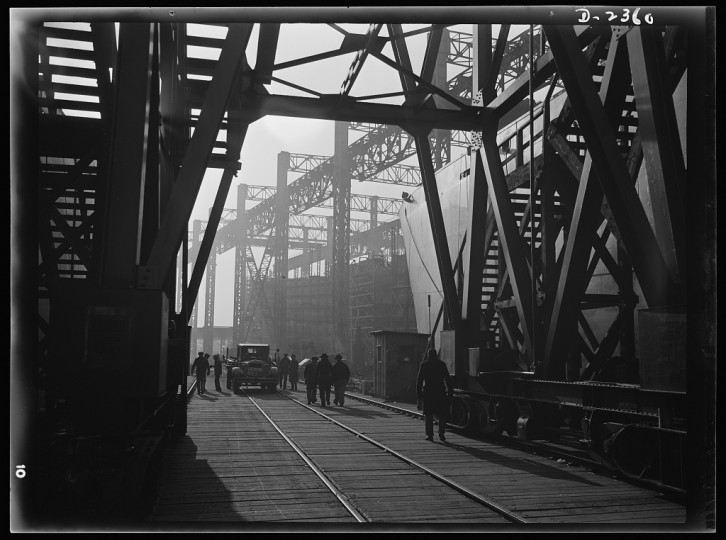

- A view from the water of the shipways at a large Eastern yard. At the left is seen the old-style superstructure, with tracks for two-way overhead cranes, while at the right, running on ground tracks, are the more modern cranes, designed for hoisting from any angle. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- These are prefabricated bulkhead sections for ships of the Liberty Fleet being welded together before they are hoisted into position in a new ship in front of a large Eastern yard. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

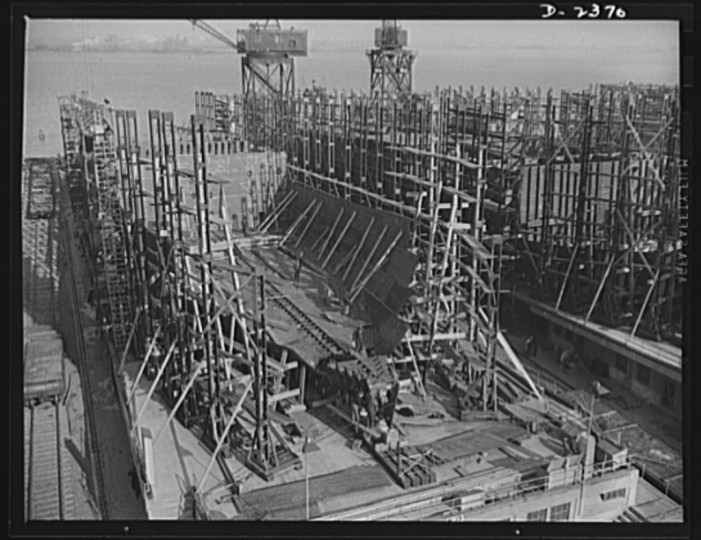

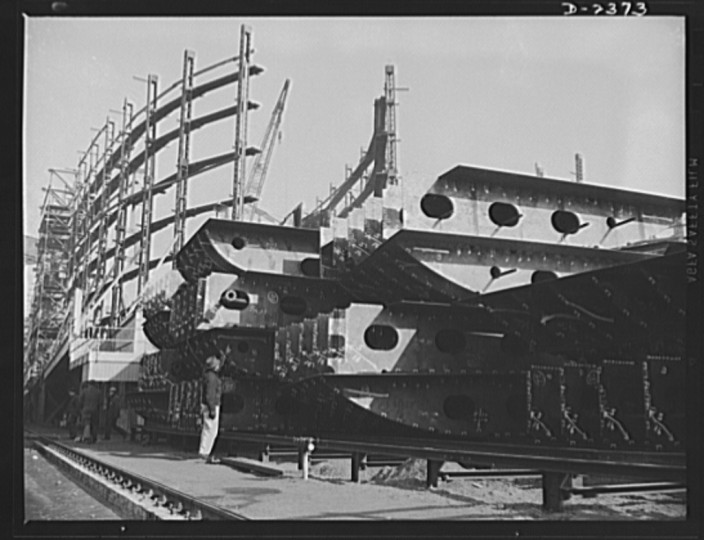

- This is the midship section of a new member of the Liberty Fleet, nearing completion at a large Eastern shipyard. In the background is a maze of scaffolding and cranes typical of the scene in many large American shipyards as builders work to make Uncle Sam master of the seas

- All assembled and ready to go in place. Prefabrication of sections such as this in a nearby plant formerly making freight cars saves weeks in the building of ships for Uncle Sam's new merchant fleet. This piece is being hoisted into place, and soon the welder will begin his vital work. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- This is the midship section of a new member of the Liberty Fleet, nearing completion at a large shipyard. In the background is a maze of scaffolding and cranes typical of the scene in many large American shipyards as builders work to make Uncle Sam master of the seas

- All assembled and ready to go in place. Prefabrication of sections such as this in a nearby plant formerly making freight cars saves weeks in the building of ships for Uncle Sam's new merchant fleet. This piece is being hoisted into place, and soon the welder will begin his vital work. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- A new vessel has just moved off these ways, and the keel is being assembled for yet another, in a large Eastern yard. The bottom and side shell plating and the inner tank sections are being assembled. Another new keel has been laid on the ways to the left. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars

- This is the midship section of a new member of the Liberty Fleet, nearing completion at a large Eastern shipyard. In the background is a maze of scaffolding and cranes typical of the scene in many large American shipyards as builders work to make Uncle Sam master of the seas. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

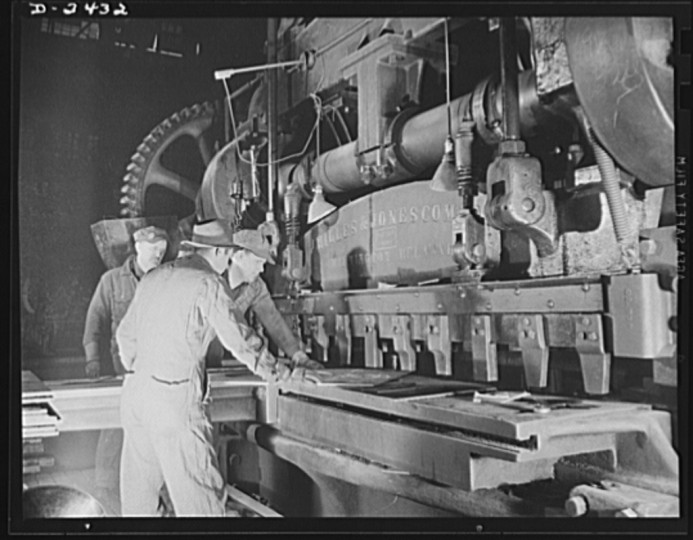

- Workers at a prefabricating plant turn out steel parts for a large Eastern shipyard building units of Uncle Sam's "Liberty Fleet." Here they operate a giant shear. This plant was originally used to produce freight cars, and the shears are part of the plant's original equipment. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flatcars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Workers at a prefabricating plant turn out steel parts for a large Eastern shipyard building units of Uncle Sam's "Liberty Fleet." Here they operate a giant shear. This plant was originally used to produce freight cars, and the shears are part of the plant's original equipment. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flatcars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Ships for war has meant the rehabilitation of numerous odd pieces of equipment unused for long periods, both in shipyards and in various other plants engaged in production of parts for ships. A discarded steam locomotive in a large Eastern yard is being tuned up for use once again. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flatcars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Welding is more important than ever before in shipbuilding, saving time, weight and steel. This work is done at a nearby plant which formerly turned out freight cars. These workers are doing a dual welding operation on fuel oil tanks for the bottom of a "Liberty Ship" under construction at a large Eastern yard. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flatcars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Welding is more important than ever before in shipbuilding, saving time, weight and steel. This work is done at a nearby plant which formerly turned out freight cars. This worker is welding top plates to angle frames for a merchant ship under construction at a large Eastern yard. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flatcars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Welding is more important than ever before in shipbuilding, saving time, weight and steel. This welder is working on the foundation for steel pillars to support the decks on top of the shaft tunnel of a new merchant ship under construction at a large Eastern plant. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flatcars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

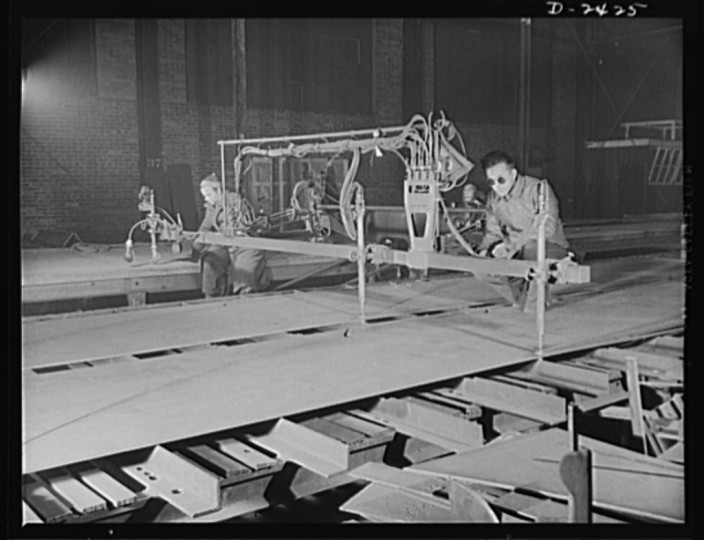

- This is a travograph-oxy-acetylene machine, a cutter which treads its own pattern. Here it is cutting two identical floor plates for a tank section at the bottom of a new member of the "Liberty Fleet." The work is done at what was formerly a freight car plant now a large Eastern plant. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flatcars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Red-hot, this steel plate is shaped on the mold to form a stern section for a member of the "Liberty Fleet," under construction at a large Eastern shipyard. The work is being done at a nearby plant formerly used for the building of freight cars. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flatcars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Red-hot, this steel plate is shaped on the mold to form a stern section for a member of the "Liberty Fleet," under construction at a large Eastern shipyard. The work is being done at a nearby plant formerly used for the building of freight cars. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Red-hot, this steel plate is shaped on the mold to form a stern section for a member of the "Liberty Fleet," under construction at a large Eastern shipyard. The work is being done at a nearby plant formerly used for the building of freight cars. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- This worker in the mold loft is painting over the marks made on steel plates from wooden templates, or patterns. The original marking is scratched onto the steel, and this man brings them out in white. All parts are prefabricated in this huge Eastern plant which turned out freight cars. The completed sections are then carried six miles to the ways on flatcars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Workers at a prefabricating plant turn out steel parts for a large Eastern shipyard building units of Uncle Sam's "Liberty Fleet." Here they operate a giant shear. This plant was originally used to produce freight cars, and the shears are part of the plant's original equipment. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flatcars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Here are two members of the Liberty Fleet lying at anchor in the basin of a large eastern shipyard, awaiting final fitting and rigging. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Here are two members of the Liberty Fleet lying at anchor in the basin of a large Eastern shipyard. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- These flat cars loaded with prefabricated and assembled sections for ships under construction at a large Eastern yard are leaving nearby plant formerly used for the manufacture of Pullman cars. The work of this plant means many valuable months saved in building of Uncle Sam's Liberty Fleet. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem- Fairfield Shipyards Inc., Baltimore, Maryland

- This worker is watching for signals from a colleague as he rolls cold steel plate to a desired shape on this plate roller, designed in Germany. All parts are prefabricated in this Eastern plant which formerly turned out freight cars. The completed sections are carried to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- The maritime inspector at a large Eastern shipyard is checking over, with the foreman, the stem assembly for a new member of the "Liberty Fleet." All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Nearly ready to be hoisted into place on the deck of a new ship under construction at a large Eastern yard, this mast is given its final coat of paint

- Between the ways of this large Eastern shipyard run tracks for flat cars carrying materials or sections to be hoisted onto the decks of ships under construction

- Here are two members of the Liberty Fleet lying at anchor in the basin of a large Eastern shipyard, awaiting final fitting and rigging

- Here are two members of the Liberty Fleet lying at anchor in the basin of an Eastern shipyard, awaiting final fitting and rigging. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Between the ways of this large Eastern shipyard run tracks for flat cars carrying materials or sections to be hoisted onto the deck of ships under construction

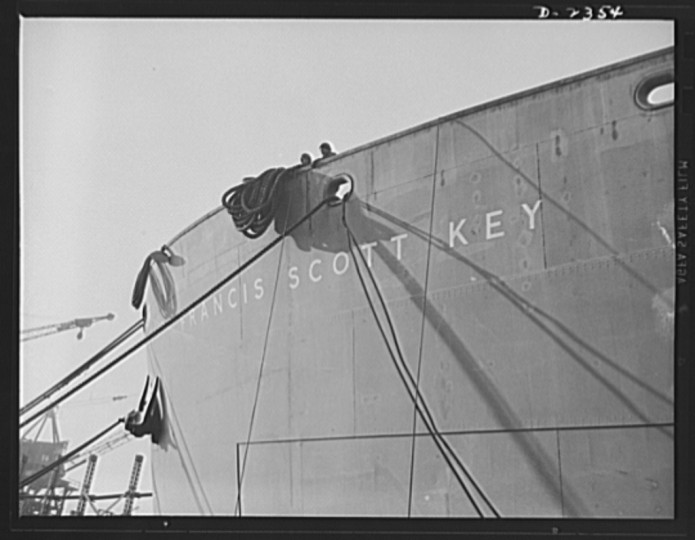

- This is the bow of a new Liberty Fleet member, awaiting its hose or template at a large Eastern shipyard. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- In the foreground is the track of a two-direction overhead crane, while in the background may be seen more flexible modern cranes. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Use of a former Pullman car plant for the prefabrication of many sections used in the ships being built at a nearby yard means the saving of many valuable months in our shipbuilding program. This man is a brakeman on a train carrying assembled sections from the plant to the yard. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Most large shipyards have their own rail systems, with several locomotives and flat cars used for hauling heavy ship parts about the yards. This man operates such a locomotive transporting completed sections from a former freight car plant six miles to the ways where they are assembled into completed ships. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flat cars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- In an abandoned freight car factory near the Atlantic coast, sections of sleek freighters for the merchant fleet are being prefabricated. Present rate of production is one a week. The men shown at work here believe they can increase that rate to one in six days

- These flatcars loaded with prefabricated and assembled sections for ships under construction at a large Eastern yard are leaving a nearby plant formerly used for the manufacture of Pullman cars. The work of this plant means many valuable months saved in the building of Uncle Sam's "Liberty Fleet." All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flatcars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- Welding is more important than ever before in shipbuilding, saving time, weight and steel. This work is done at a nearby plant which formerly turned out freight cars. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flatcars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- This giant plate roller, of German design, is used to roll cold steel shell plates for members of Uncle Sam's new "Liberty Fleet" under construction at a large Eastern shipyard. This prefabrication work is being done at a nearby plant which formerly turned out freight cars. All parts are prefabricated in this huge Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flatcars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

- These are rolled plates for the shaft tunnel of one of Uncle Sam's new "Liberty Ships," under construction at a large Eastern shipyard. All parts are prefabricated in this large Eastern plant which formerly turned out freight cars. The completed sections are then carried six miles to the ways on flatcars. Bethlehem-Fairfield Shipyards Inc., Baltimore, Maryland

Liberty Ships built in Brunswick, Glynn Co., Georgia During World War II

Liberty Ships World War II Due

to enemy U-boats during 1942, millions of tons of ships and cargo were

lost during WWII. This high loss necessitated the need for more ships

that were stronger, larger, and can hold vast amounts of cargo.

During 1942 the U.S. Maritime Commission chose 16 sites around the

nation to build what would be termed "Liberty Ships." Brunswick was one

of the towns chosen.

Due

to enemy U-boats during 1942, millions of tons of ships and cargo were

lost during WWII. This high loss necessitated the need for more ships

that were stronger, larger, and can hold vast amounts of cargo.

During 1942 the U.S. Maritime Commission chose 16 sites around the

nation to build what would be termed "Liberty Ships." Brunswick was one

of the towns chosen.Headed by the J.A. Jones Construction Company, about 99 ships were built by the 16,000 plus employees of Brunswick's shipyards. In 1943 the first keel was laid for one of these 447 foot, 3500 ton steel vessels, vessels that sailed across the oceans anonymously so that the enemy would have no idea as to what these ships were up too. Four ships were produced each month, the last month of production, during the Battle of the Bulge, 6 ships were requested to be made. The patriotic citizens of Brunswick rallied around their shipyards and produced seven vessels to aid the war effort.

Each ship was christened with a name before setting off, most named after important men of the time and of the nation's history.

Upon war's end in 1945, the J.A. Jones Construction Company closed the shipyards, on their way out, they donated a model of one of the Liberty Ships that was used in training the employees. For many years this model sat at the foot of the St. Simons Island Causeway, eventually though, the model fell to ruins and had to be scrapped.

Around 1987 the local Navy League started raising funds to build a new model. On 23 August 1991 a brand new 23 foot vessel was completed, making it the "100th Liberty Ship" build by Brunswick. And, like all vessels before it, this ship was christened with a bottle of champagne and the name "City of Brunswick".

Σχόλια

Δημοσίευση σχολίου